Omega Plastics was recently challenged with a project that required high precision/very tight tolerances, a very expensive resin, along with requiring a very small shot size. Their existing, traditional, molding equipment presented a serious concern, especially regarding the issue of material residence time.

|

|

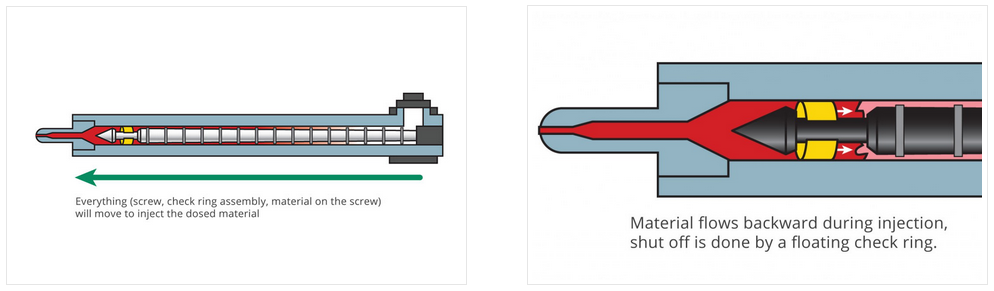

Traditional Injection Molding mechanical process Issue |

Through diligent research, Omega’s Molding Specialists’ discovered a piece of equipment that, on paper, seemed to deliver a process that resolved the project concerns.

Sodick offers a unique approach to injection molding by separating the plasticizing of resin from the actual injection process using what they call their 2-Stage Plunger Injection System or “V-LINE®” Injection.

After a visit to Sodick’s manufacturing facility, Omega’s Molding Specialists were sold on the GL30A and the press was added to Omega’s ‘Cleanroom’ inventory.

The GL30A is Sodick’s flagship machine for critical tolerance parts that require extreme precision with both material preparation and injection dosing accuracy. Using the two-stage plunger injection molding system, molders are provided with an ‘Exact Dosing’ capability.

The following are several key advantages Omega has gained since adding the GL30A:

• The extreme acceleration of the plunger enables “downsizing” of runners and improve on the overall process.

• Accuracy / repeatability and “stable molding” when using the GL30A. Small process “strike zones” are target applications for this machine.

• Push the Limit with Thin Wall Applications

o Up to 1,500 mm/sec (59”/sec) speed

o Up to 343 MPa (49,750 psi) pressure

• Small Shot Size from 2.0cc (0.07oz)

o High dosing accuracy combined with an ultra-repeatable process

o Quick response in injection acceleration & deceleration

o Accepts standard size pellets

• Optimum Injection Unit Size

o High temperature heaters – standard

o Wear resistant screw and barrel – standard

o Optional large clamp with small injection

o Optional bigger screw with smaller plunger

o Shot usage from 10% of total shot or less

The GL30A is also equipped with 788 F high temperature heater bands, standard, because it is common to run many engineering grade materials like PEEK, PEI, PPS, LCP, etc.

About Sodick Co. Ltd.

As a leading precision injection mold machine manufacturer, Sodick continues to pave the way in providing premier injection quality and repeatability. Our proprietary technology relies on a continuous plasticizing heat profile, constant material viscosity, as well as steady filling volume and holding pressure.

Through the development of our V-LINE Two-Stage Plunger design and our wealth of experience as a leading EDM manufacturer, this exclusive technology is THE solution for precision molding requirements.

Based out of Kaga, Japan, Sodick Co. Ltd began the design and development of the V-LINE Plunger Injection Molding Machines in 1988 and continues to this day. Sodick continues to push the limits of molding applications as the only manufacturer with the exclusive V-LINE Two-Stage Plunger technology.

Offering both Horizontal Injection Molding Machines from 10 to 650 tons and Vertical Injection Molding Machines from 3 to 150 tons, Sodick offers solutions for thermoplastic, micro molding, insert molding and LSR-Silicone applications for a wide range of industries.