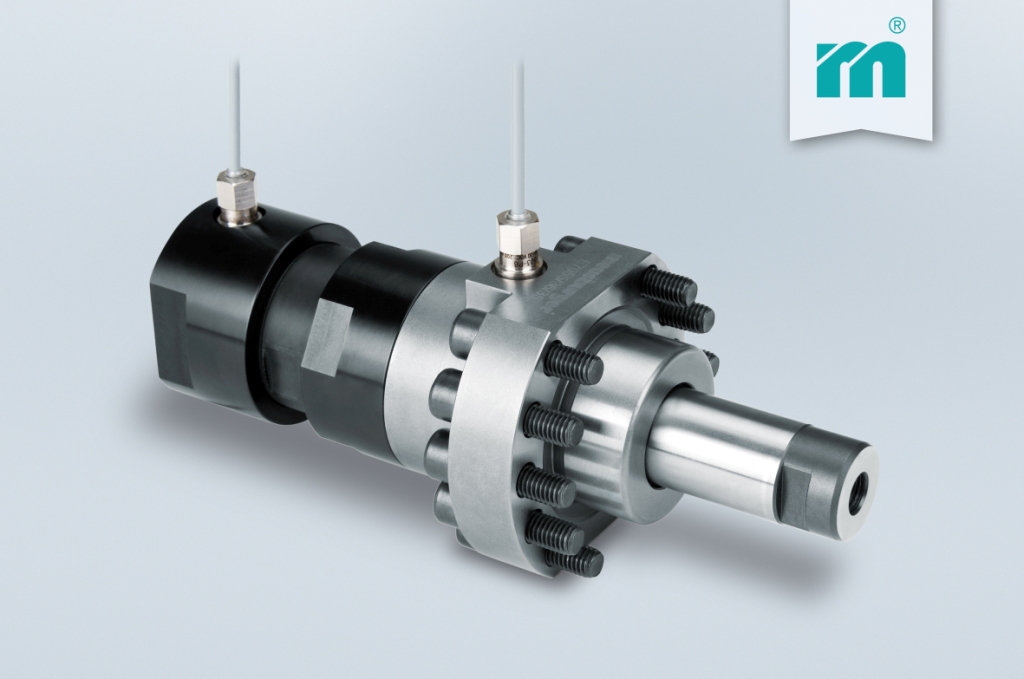

Meusburger develops new locking cylinder for core pullers and slides

|

The Austrian standard parts manufacturer offers its customers an optimal solution with the E 7055 Locking cylinder which is especially suitable for core pullers and slides for injection moulding and die casting. A large surface on the slide or core puller results in high forces which can usually only be absorbed by very large hydraulic cylinders. The locking cylinder with mechanical locking in the end position offers a very high load capacity even with a compact design and provides an ideal solution for the designer. The practical flange design enables a defined position of the oil ports and the sensors which provide high process reliability through end position monitoring. On plastic parts which have an aperture the cylinder is mounted with preload to prevent burr forming. However if the core is free in the injection-moulded part, the cylinder is installed without preload. The E 7088 Adapter for locking cylinder enables easy connection on the slide or core puller. The new locking cylinder from Meusburger is available from stock with retaining force from 40 to 500 kN and with the corresponding attachments.