The technical plastics polyamide 6 and polyamide 66 are admittedly materials with very similar properties, yet they are frequently in competition to one another. Recently, the tense pricing situation for polyamide 66 and its temporarily limited availability have resulted in it often being replaced with polyamide 6 even in its traditional applications. However, new developments of components that have traditionally been made from polyamide 66 are now increasingly being directly implemented in polyamide 6.

|

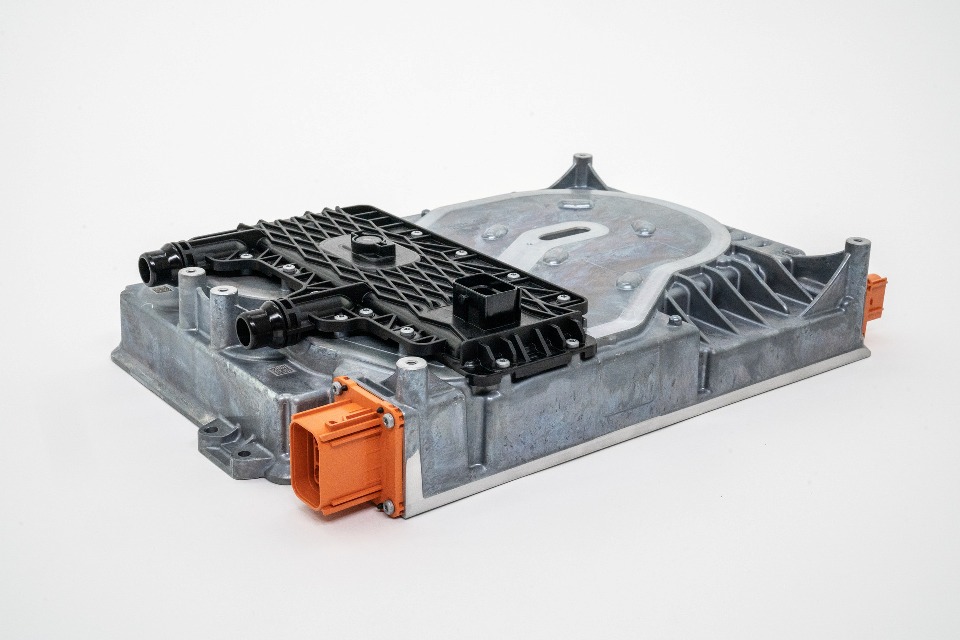

One current example of this is the cover for an on-board battery charger that is used in an all-electric compact vehicle made by a German car manufacturer. It is composed of Durethan BKV50H3.0 from LANXESS, which is highly reinforced with 50 percent by weight of short glass fibers. The manufacturer of the system consisting of the cover and charger is Leopold Kostal GmbH & Co. KG, Luedenscheid, Germany, a global system supplier of automotive, industrial and solar electrics as well as electrical connector systems.

This large-scale application underlines the fact that polyamide 6 compounds do not necessarily have to be hydrolysis-stabilized to be used in cooling applications with glycol-water coolants in electric vehicles. “We assume that in the future, polyamide 6 products of this type will become very common in the mass production of covers and other thermal management components for electric vehicles. That is especially the case for applications such as fluid connectors or control units in the cooling system,” explains Dr. Bernhard Helbich, Technical Key Account Manager at LANXESS’ High Performance Materials business unit.

|

Permanently leak tight and resistant

Plastic components in the cooling circuit of combustion engines have long been a domain of polyamide 66. This is because the thermoplastic is highly resistant to hot coolants such as water-glycol mixtures. However, the requirements in the thermal management of purely electric powertrains are shifting toward lower temperatures. For all-electric vehicles, the long-term thermal resistance of polyamide 6 compounds to water-glycol mixtures is sufficient for most of the parts, even for the significantly longer stressing times in some cases. Thus, the cover permanently withstands temperatures of up to 85 °C during vehicle operation without any problems, and burst loads of up to 10 bar are achieved. Long-term tests on test specimens also revealed that the mechanical properties of the compound in water-glycol mixtures hardly diminish even after 1,500 hours of storage at 110 °C and a pressure of 1.5 bar. As a result, the material meets the technical requirements of a major German carmaker for water-cooled components of electric vehicles.

High degree of strength and stiffness

At around 29 centimeters long and 12 centimeters wide, the cover has a considerable flange length. The cover, together with a seal, is screwed to the aluminum housing of the charger. The high degree of strength and stiffness shown by the polyamide 6 compound ensures that the cover meets the strict leak tightness requirements. Helbich comments, “To that end, we optimized the mechanical component properties in close collaboration with Kostal and, by simulating filling, we determined how minimum values for shrinkage and warpage can be achieved in injection molding processing. These services are part of our HiAnt service package, with which we support our project partners at all stages of component development.”

In addition, the cover exhibits other material advantages of Durethan BKV50H3.0. For example, it is easy to process and can be injection-molded at high injection speeds, which benefits short, and therefore economical, cycle times. Furthermore, its copper-free H3.0 thermal stabilization does not result in electrical corrosion occurring on metallic parts in the cooling circuit. Another of the compound’s virtues is that it is resistant to media typically found in vehicle operation, such as oils, greases, battery electrolyte, and road salt.