Arkema, a leader in specialty materials & a pioneer in high-performance materials for 3D printing, continues its development in additive manufacturing and provides innovative and more sustainable new material solutions for all major 3D printing technologies.

|

Liquid resins for UV curing

Arkema offers an integrated line of performance liquid materials for UV-curable 3D printing, through N3xtDimension® custom formulations for customer-specific product development, N3xtDimension® engineered resins for targeted advanced performance, and Sartomer® specialty resins and additives to fine-tune end formulations.

At Formnext, Arkema introduced two new high-performance custom formulations to extend its leading range for UV-curing:

• N3D-HITEMP062: hybrid high temperature material with excellent toughness and high HDT properties.

• N3D-CAST063: very high-resolution material, enabling matte finish so that details can be easily seen and a melting behavior during burnout for high quality castings.

Within their engineered resins portfolio, Arkema also introduced a new elastomeric material with an outstanding balance between elongation at break of 170% and tear strength of 33 kN/m, leading to excellent mechanical properties for functional parts.

|

Powder bed fusion

At the exhibition, Arkema was displaying new solutions for powder bed fusion technologies, led by flagship brands such as Rilsan® bio-based polyamide and Kepstan® PEKK high performance thermoplastic.

• Resulting from continuing collaboration on responsible manufacturing, Arkema and EOS are pleased to announce the future release of a new carbon neutral PA1101.

• Arkema and EOS will launch together a new Kepstan® PEKK powder for the EOS P 810 system, delivering higher ductility, excellent electrical insulation and higher recyclability, to fulfill the needs of high temperature applications in Oil & Gas and Electrical & Electronic markets.

|

Filament

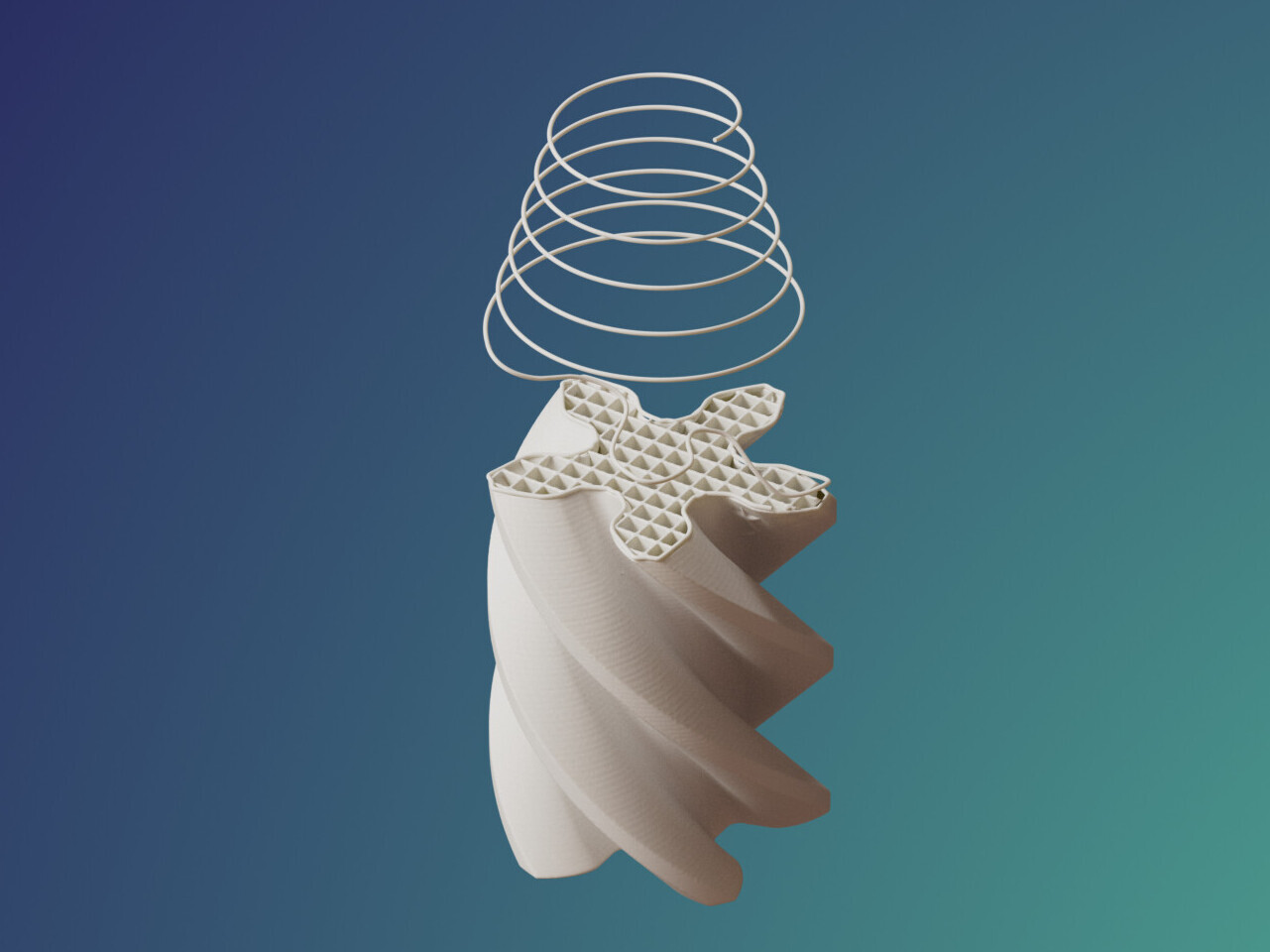

With a dedicated range of advanced polymers for filament extrusion printing technologies, Arkema is pleased to announce the release of Kimya Kepstan® PEKK-SC 3D filament on Stratasys Validated Material Ecosystem, developed with our partners Stratasys and Kimya. This high performance thermoplastic filament goes beyond expectations to perform in the harshest industry environments such as end-use Oil & Gas applications like back-up rings.