Thermal stability and curing behavior of acrylate photopolymers

Additive manufacturing (AM) of plastics is one of the most promising technologies in the 21st century. Near-unlimited design freedom allows the technology to be utilized in a broad range of industry sectors, such as the medical field, consumer goods and the automotive industry.

|

In 2021, photopolymers or UV-light activated polymers ranked second behind polymer powders in AM materials sold worldwide, with a market share of 25.2%. This market share can be explained by the utilization of these materials in AM technologies such as Material Jetting and Vat Photopolymerization, which demonstrate a high maturity and distribution within the private sector as well as industrial applications. (Source: Wiley Online Library)

In the Wiley Online Library publication, Polymer Engineering & Science the Technical University of Munich (Professorship of Laser-based Additive Manufacturing, Department of Mechanical Engineering) and experts from NETZSCH Analyzing & Testing analyzed next-generation additive manufacturing processes based on UV-curing acrylate photopolymers. This was with the aim to extend the barriers of functional part production by deploying rapid processing speeds, complex geometries with high resolutions, and an extended material spectrum.

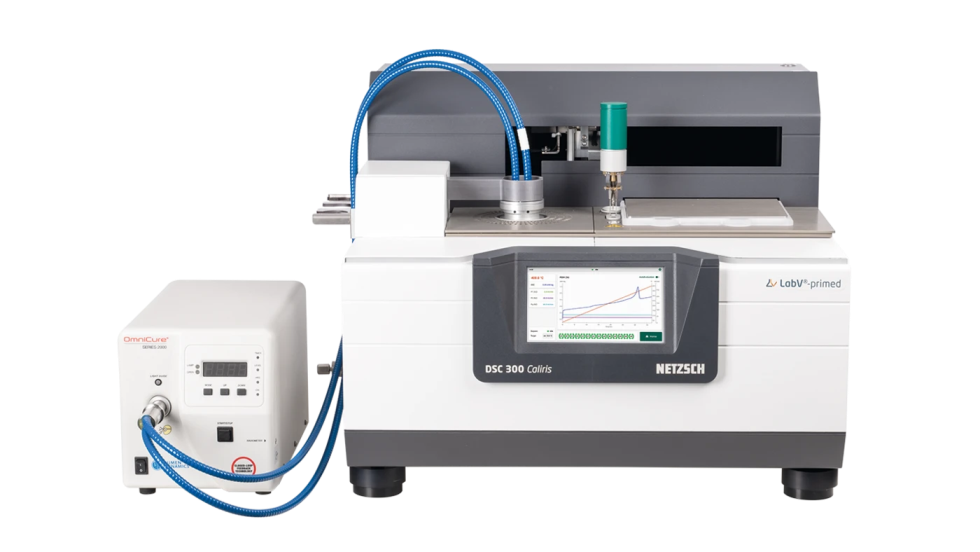

Using two NETZSCH analysis instruments Photo-DSC 204 F1 Phoenix® and PERSEUS® TGA 209 F1 Libra® they concentrated on the experimental analysis of the thermal decomposition behavior with subsequent calorimetric analysis of the curing behavior of different acrylate systems.

In this context, the following key aspects were investigated:

1. The influence of increased isothermal temperatures during UV-curing on the speed and extent of the reaction of the analyzed acrylate systems.

2. The utilization of the UV-intensity as a tool for strategic variation of the curing speed and the degree of cure of the analyzed acrylate systems.