From smart health patches to continuous glucose monitors to smart glasses, the use of medical wearables and consumer wearables for remote monitoring has increased dramatically. The shift from hospital care to remote home care has led to a demand in remote tracking and diagnostics. Devices are smaller, require better environmental protection and reliable diagnostics, while maintaining patient safety and comfort. These advancements in medical device design require innovative solutions to optimize devices and processes beyond today’s level of care.

|

|

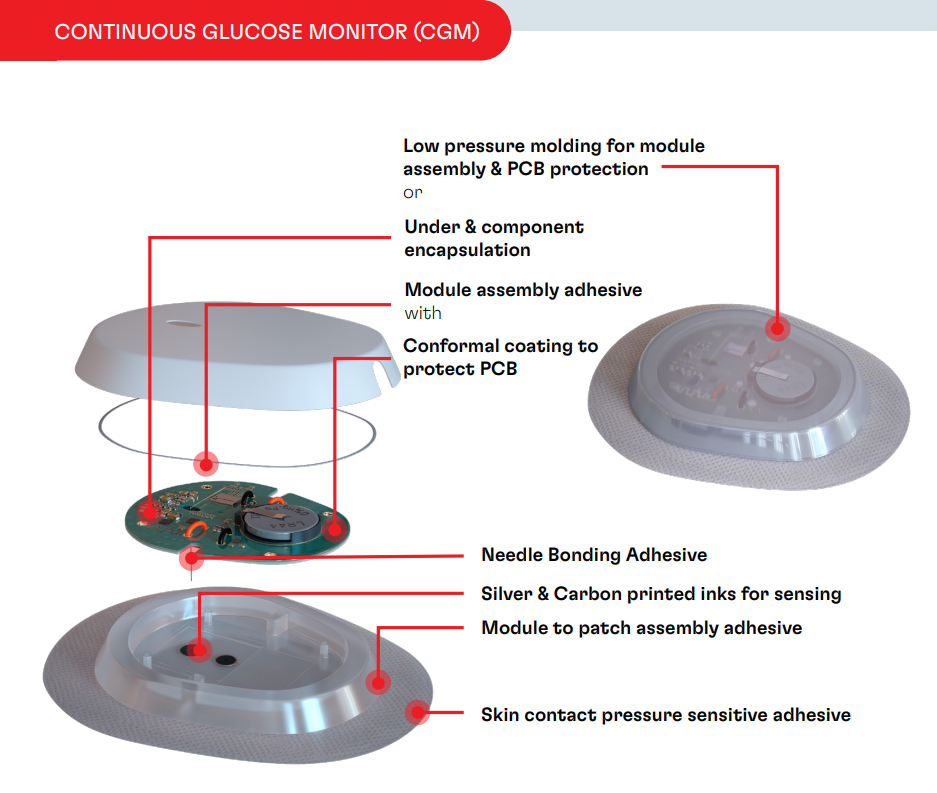

Henkel offers a broad product portfolio and solutions for medical wearables such as CONTINUOUS GLUCOSE MONITOR (CGM) |

For decades, Henkel’s adhesives and electronic materials have facilitated the design and manufacture of leading-edge medical devices, all engineered to streamline diagnostics and improve patient outcomes. The combination of the company´s materials know-how with its longstanding industry expertise continuously enables the co-development and support of medical solutions for caregivers and patients to improve quality of care and life.

Based on this experience Henkel now has expanded its portfolio for wearables in healthcare applications. Therefore, the company leverages its unique capabilities and broad portfolio of high-performance materials for a variety of wearable application types alongside the entire value chain. Henkel´s technology portfolio includes high-impact solutions for low pressure molding technologies, skin bonding, assembly adhesives and electronics and printed electronics.

Recently, the company has worked to adapt a molding technology, that was traditionally used in industrial electronics, for wearable medical applications. The new technology is medical grade and skin safe and replaces the typical clamshell housing, which requires multiple components and assembly steps, with a single step over-mold design. With this technology Henkel offers a significant process saving step that contributes to lower production cost, especially when there is a high volume of production.

“At Henkel, we believe that offering a comprehensive portfolio of products and solutions to our customers is the sustainable way to drive innovation and growth for businesses,” explained Philipp Loosen, Head of Industrials EIMEA and Global Key Accounts Medical at Henkel. “We are proud to expand our product portfolio of medical wearables into the market to further support our customers and eco-system partners with an efficient and reliable healthcare solution. With our products and technologies, we help to redefine the way people access and monitor their health.”

Henkel's Medical Device Adhesives are tested to the industry’s most comprehensive ISO 10993 biocompatibility standards. In addition, the company employs strict manufacturing and quality controls to ensure continuity of compliance.

Henkel was showcasing its wearables portfolio at the 44th WEARABLE TECHNOLOGIES CONFERENCE 2023 USA from August 1-2, 2023, in Fort Mason Center, San Francisco (USA).