In recent years, thanks to its innovative, universally applicable modular system of technologies, Fill has developed into a full-range supplier to the international aerospace industry in the field of NDT testing processes. The customized NDT developments made by Fill are individually tailored to customer requirements. The company supplies customers from all over the world with high-precision machine technologies as well as specially developed, complementary software solutions. The company is currently working on numerous orders, primarily from the aerospace industry in Europe and Asia.

|

|

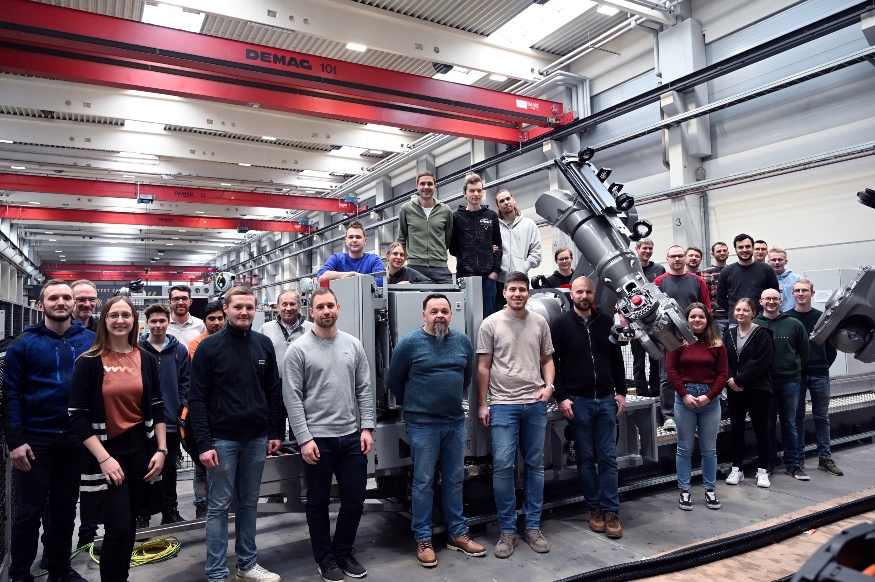

The NDT solutions are powered by a motivated team at Fill whose members are constantly working to further develop non-destructive testing methods and make aviation even safe |

In 2009, Fill began building the first NDT (Non-Destructive Testing) test systems in collaboration with the aerospace company FACC. Initially, Fill acted as a supplier of mechanics, while the technology mostly came from the customers. The Upper Austrian mechanical engineering company is now in demand worldwide as a provider of complete solutions. The Fill development teams are constantly working on and expanding a kind of modular system of technologies (ultrasonic, X-ray, thermography, etc.). With the NC-controlled articulated arm robots, they have succeeded in setting an international benchmark. This type of kinematics is much more flexible and multifunctional, which means that it can be tailored to specific customer requirements and not only meets, in some cases even exceeds, the strict criteria of the global aviation industry. "Our developments have put a unique machine system on the market. Customers from all over the world come and go at our headquarters in Gurten, Upper Austria, and are impressed by the variety of possible solutions. There is an enormous dynamic in this area," reports Wilhelm Rupertsberger, Head of the Plastics Competence Center at Fill.

Maximum precision ensures safety

With the ACCUBOT, Fill has succeeded in developing what is probably the most precise robot available to the aerospace industry. Based on the powerful path planning capabilities of the Siemens Sinumerik controller, the mechanics were expanded to include direct measuring systems at the robot joints in order to eliminate backlash and other negative influences from the gearbox. In combination with the automated ultrasonic inspection systems ULTRASONIC INSPECTION and X-RAY INSPECTION, the complex structural parts of the aerospace industry undergo state-of-the-art inspection procedures. The term NDT (non-destructive testing) is used when a test procedure allows you to look through and into the components without destroying them.

The central indexing table

FILL STUDIO, developed by Fill technicians, is the central control software. All operations and processes are managed using this software. This allows processes to be tested for feasibility in advance and transferred to the respective system control via a post-processor. This saves valuable production time.