The new modular electric IMM series sets a new standard in being flexible, highly precise and efficient during the entire service life

KraussMaffei premiered its new PX injection molding machine series at the recent K 2016 show. The new machines stand out by unprecedented modularity combined with an all-electric concept, which makes the customers benefit constantly from increased productivity, high precision and flexibility provided.

Focused on Flexibility

Injection molding machines using the all-electric concept have been known for their efficiency and precision, but also for quite limited options. Dr. Hans Ulrich Golz, Managing Director of KraussMaffei, also serving as the President of the IMM segment at the KraussMaffei Group, explains: “Until now, customers have most often been forced to decide between low-budget and high-end designs. KraussMaffei is now presenting the first all-electric machines on the market, which the customer may tailor to its specific manufacturing needs” — yes, just as the modular concept goes for hydraulic machines. “This includes, for example, larger platens, faster injection speeds, more ejector force or the capacity to be operated with food-grade NSF H1 lubricants,” adds Dr. Golz.

At the K show this year, an all-electric toggle machine series with clamping forces ranging from 500 to 2,000 kN was premiered. The series was designed and created with an eye on flexibility spreading throughout the service life of the machines — from their acquisition to everyday operation to retrofitting. The all-electric PX machines have advantageously inherited the tried and true modularity of hydraulic series by KraussMaffei.

A multiplicity of options

|

|

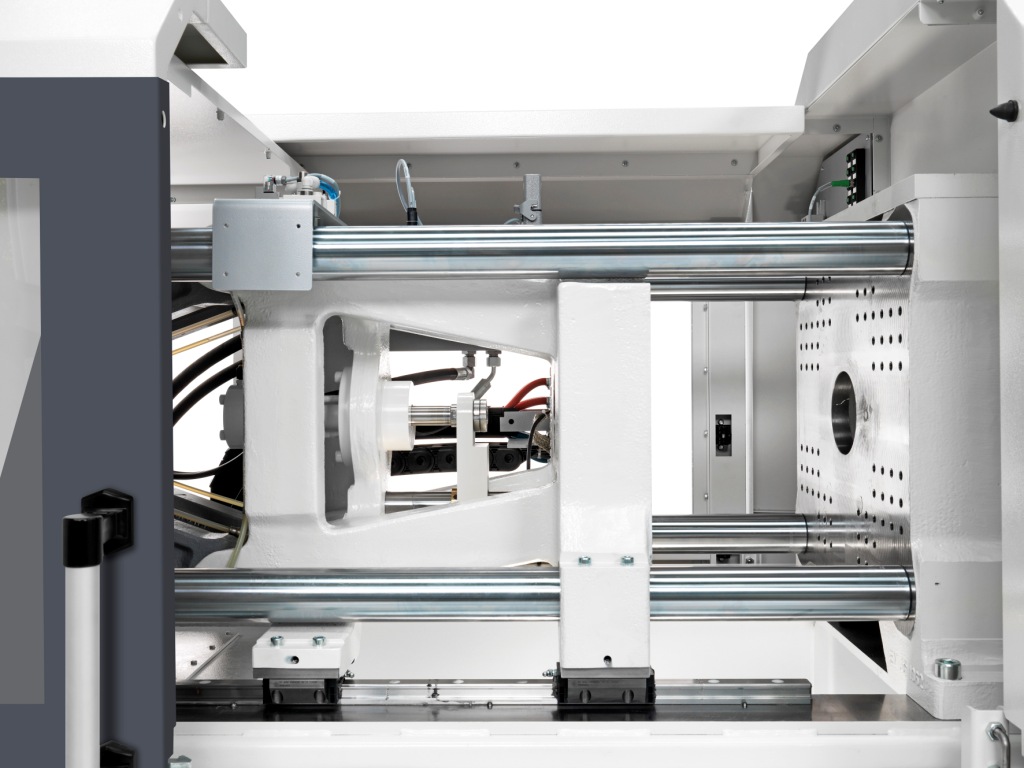

The broad support of the movable mold platen on linear guides guarantees optimal platen parallelism. |

The new all-electric machines are highly adaptable as proven by two crucial features. First, the combination of clamping unit and injection unit can be chosen from a wide array of options for the sake of maximum customizability. This means you can combine e.g. small injection units with large clamping ones: no extra space is taken by what is not essential for production.

It is worth noting that large clamping units are among the clear choices, as platens of certain standard PX versions are larger than those of respective core models are. Actually, these “intermediate” PX models, identified by odd numbers (PX 51 to PX 161), have platens corresponding to the machines of next higher clamping force. This increases maximum mold weight to about 750 kg for a PX 51 compared to 450 kg for a PX 50. Thus, heavy molds receive the needed linear support with a precise parallel movement.

For a clamping unit, five highly efficient injection ones are available, each for a certain performance level. In turn, for every injection unit, three or four screw diameter options are proposed.

All-electric drive enhanced by servo hydraulics

|

|

The injection unit with two parallel injection unit barrels builds up nozzle contact force quickly and symmetrically. |

The fact that electric motors operate autonomously meets perfectly the focus on flexibility, letting any number of processes run simultaneously for rapid operation. The three principal axes of a PX machine — these of the injection, the plasticizing and the clamping units — have servomotors with air-cooling, allowing for a remarkable energy efficiency and low water consumption. In addition, the servomotors operate in the so-called recuperative mode with up to 60% of braking energy being converted back to electric power, stored provisionally and either fed back to the power supply or consumed directly by the machine.

The secondary injection and ejector axes of PX machines are driven by servo hydraulics as standard. The movement of injection unit is initiated by two barrels working in parallel, preventing the appearance of lateral forces and providing for a very rapid buildup of nozzle contact forces. For high-throughput applications such as thin-walled injection molding, injection speed may be more than doubled for a considerably increased plasticizing output. The injection unit may also come swiveling for an easy screw or retaining valve change.

When it comes to ejectors, servo hydraulics equates robustness. For example, demolding of plastic items using a vibroplaten induces mechanical impacts on sensitive electric drives, but durable servo hydraulics withstands the impacts reliably. Customers not using vibrating devices in their production and wanting an especially high precision can optionally equip a PX machine with an electric ejector drive.

“Geometry, force and speed” as the pillars for successful clamping

|

|

The PX can be equipped or retrofitted with extensive close-to-the-mold hydraulic cooling water circuits. |

“Three things matter when it comes to the clamping unit: geometry, force and speed. In all three areas, the PX offers options for coordinating the machine to meet individual requirements,” emphasizes Dr. Golz.

In addition to the above-mentioned extra wide support of moving platens on linear guides in odd-numbered models, tie bars of the new machines are kept clean of lubricants, and the entire area under the clamping unit remains totally unobstructed for logistics needs. This means no crossbeams get in the way when putting conveyor belts or containers for finished parts under the machine. All of this is thanks to a special design of clamping unit, particularly its bed. Moreover, mold height limit can be increased by approximately 100 mm compared to the standard machine version, e.g. from 450 to 550 mm for a PX 120. Mold height is adjusted automatically.

Electric or hydraulic, ejectors require high forces for items shrinking on cores. That is why the new machine series has an option of ejector force increase by half. The same goes for ejection speed: 700 mm/s is reachable compared to 350 mm/s, which is ideal for swift production.

Working height of PX series machines of any clamping force is constant and very convenient: 130 cm. The mold and the nozzle are thus highly accessible during both setup and production. The machines boast an extremely reduced water and power consumption, especially for the equipment with such an elevated availability and precision in operation.