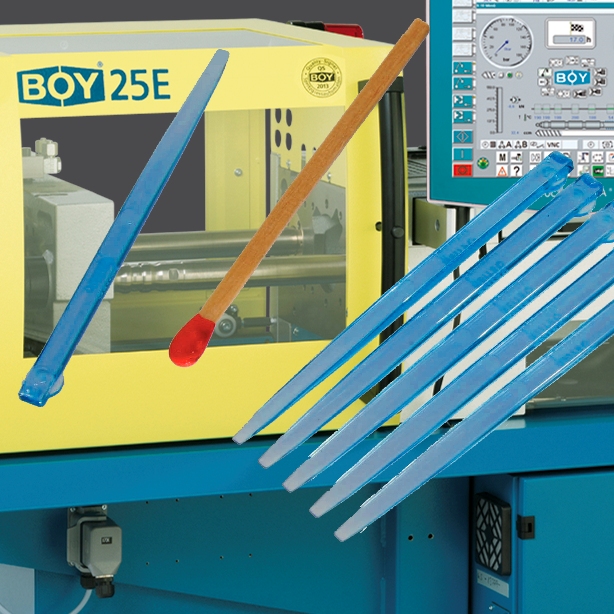

At the Technology Day Hein in Hannover-Langenhagen on 15th February, 2019, BOY will score with its largest exhibit so far. A BOY 25 E (with a clamping force of 250 kN) produces practical toothpicks at the exhibition booth in the new rooms of the Brandboxx Hannover. The eight-cavity mould will demonstrate that hot runners can be used profitably even in the case of small moulded part dimensions. With a nozzle distance of only 4.5 mm for individual, regulated nozzles, many cavities can be realized in the smallest space. Precise and without waste – since without gating - injection moulding on economically operating small injection moulding machines is optimally implemented.

|

Michael Kleinebrahm, Head of BOY Application Technology from Neustadt-Fernthal, who will be on site at the Technology Day, puts it in a nutshell: "Thanks to the necessary move to Langenhagen, the Technology Day Hein, with a steadily growing number of visitors, has now expanded visibly. We have taken account of this ambitious development and are presenting the visitors with the BOY 25 E a much larger machine than in the recent years.” According to his statement, BOY has been built around 25,000 machines of this clamping force class within 50 years.

The BOY 25 E is equipped with a servo motor pump drive. In addition to its low-noise operation, this machine will impress with its dynamics and high energy efficiency. The freely overhanging cantilevered two-platen clamping unit, the large distance of tie bars and platens to uptake the 8-cavity mould from Heitec as well as the intuitive machine control Procan ALPHA are additional special features of the highly compact injection moulding machine (1.80 m2 footprint).

About Dr. Boy

Dr. Boy GmbH & Co. KG is one of the leading worldwide manufacturers of injection moulding machines with clamping forces up to 1,250 kN. The very compact, durable machines work precise, energy-saving and therefore highly economical. BOY continually sets new standards in our industry with innovative concepts and solutions. Since the company was founded in 1968 nearly 50,000 Injection Moulding Machines have been delivered worldwide. The privately owned company continues to put special emphasis on engineered performance and high-class "made in Germany" workmanship.