Innovation and expertise always applied to customers' industrial process

Frigel Group will participate in Fakuma 2023, the International Trade Fair for Plastics Processing, in Friedrichshafen (Germany) from 17 to 21 October, presenting the latest process cooling solutions, designed especially for the following Plastics fields: automotive, packaging, medical, chemical, pharmaceutical, household, etc.

Frigel is the only player with a global footprint, with more than 10.000 customers worldwide and a focus on Customer businesses. Frigel's innovation and expertise is always applied to customers' industrial process.

|

|

Microgel™ SYNCRO |

Frigel innovative solutions are focused on:

• Maximizing productivity, thanks to sigificant cycle time reductions

• Energy savings

• Water savings

“Simply Synchronized Proven Result” - RSY Microgel Syncro will be officially launched, with its own brand and identity. Frigel's target is to establish a new technology standard, another Frigel paradigm shift.

“Engineering a more efficient and sustainable industry” - Sustainability means meeting Frigel's own needs without compromising the ability of future generations to meet their own needs. The design and development of the new MDK Adiabatic cooler has been carried out having as goal an improvement of all KPI linked with the Environment. Less kW of electricity per kW of cooling and lower usage of water (up to 95% less).

Visitors will meet Frigel's engineers and they will be able to show them the best solutions for precise industrial process. Learn about Frigel's important innovations in cooling and temperature control systems:

• New Microgel RSY Syncro (provides an important increase of productivity up to +60%)

• New Adiabatic Cooler Series (centralized closed-circuit adiabatic cooling systems designed to replace old cooling tower technology)

• New 3PR 4.0 control system (complete real-time control of the entire cooling system (parameters, functions, alarms etc.)

• Thermogel TDK Series: High precision Single Zone pressurized water TCUs

• A wide range of upgraded models: Microgel RSM/RSD provides an optimized mechanical design, increased reliability and a wide range of options. Powerful pumps and precise temperature control up to 90°C ensure long-term high performance and product quality improvement with minimal cycle cooling times.

Microgel™ SYNCRO

Frigel presents to the market Microgel SYNCRO, the new machine-side unit that revolutionizes the temperature control method for injection molding. Microgel Syncro technology provides for a drastic reduction in cycle time (up to 40%), while maintaining the surface quality, dimensional characteristics and mechanical performance of the finished product. The reduction of the total cycle time is obtained thanks to the reduction of the cooling time only: this result, achieved through the digital synchronization with the molding machine, has the great advantage of not requiring modifications of the other molding parameters, with the unit communicating with the press but remaining completely autonomous and easily implemented by the operators.

MICROGEL RSY SYNCRO Series

The Microgel SYNCRO product line features more than 10 models, with cooling capacities from 16 kW to 56 kW and heating capacities from 12 kW to 24 kW.

The big difference compared to the traditional method consists in the fact that the Syncro control unit supplies cold water to the mold only during the cooling phase, drastically reducing its duration. The advantages for the customer are easily understood: increased productivity and profitability of the dedicated production cell, against an investment with an average payback time of less than 6 months.

|

|

ECODRY MDK Seires |

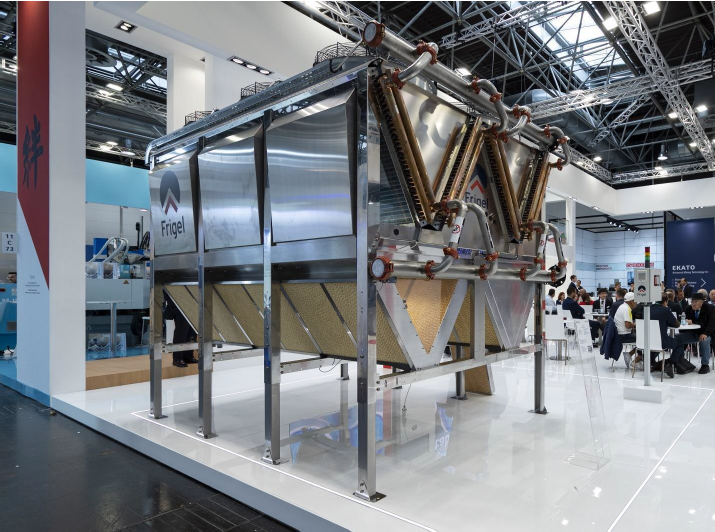

ECODRY MDK Series

Adiabatic Closed Loop Fluid Coolers with enclosed chambers and patented booster cooling technologies

Frigel expands its Adiabatic product family line, introducing the Ecodry MDK range, designed for flexible configuration of modular adiabatic solutions for small to large plastic factories. MDK takes advantage of some of the technological advances already introduced in the LDK range (new efficient PADs, new generation of EC fans, modular design, wide and deep configuration).

MDK is characterized by a high efficiency humidification system (COOLPAD™) and by a new generation of EC fans which, combined with a more effective dry cooler, obtain a new level of compactness in a powerful new adiabatic cooler product line.

The new Ecodry MDK is designed to integrate easily into existing Ecodry 3DK systems, of which Frigel has an existing installation base of thousands of units, in addition to responding to the new needs of industries, including energy efficiency, sustainability and saving of raw resources such as water.

NETGEL 3PR 4.0

Industry 4.0 Intelligent Central System Control Platform

The 3PR 4.0 product platform is a dedicated Frigel solution that provides complete control of Frigel central cooling systems. 3PR 4.0 control meets the needs of processors to supervise and manage the whole cooling system from a single control point. All the connected central system components are controlled via a unique control panel that has been designed specifically for Frigel systems. 3PR 4.0 is available in two versions, Lite and Premium, depending on the size of the system and the equipment to control.

Full native connectivity to MiND™ and its new HMI (Human Machine Interface) offer a flawless user experience and compatibility with Industry 4.0 architectures, providing easy visualization and process diagrams of the connected equipment, dashboards for main parameters, performance graphs and alarm management and history.

NETGEL MiND™ Industry 4.0 central system and machine-side Web Interface and Monitoring Platform

Frigel releases the MiND™ 2.0 platform, the evolution of its Industry 4.0 concept. MiND™ 2.0 is an innovative digital solution to meet the ever increasing needs of modern companies to reach Industry 4.0 and IIOT (Industrial Internet of Things) standards. MiND™ 2.0 is now able to provide customers a perfect supervision and maintenance tool for all Frigel equipment and accessories, both central and machine-side, allowing for monitoring and management of all working parameters and events and registering performance and energy consumption of every single cooling system component through a multifunctional user interface, both locally and remotely, through a user-friendly webpage.

THERMOGEL TDK Series

High precision Single Zone pressurized water TCUs

Frigel introduces advancements in its growingly popular direct injection pressurized water TCUs up to 120°C for applications in Automotive, Medical and any other Technical Molding sector where accuracy, repeatability and process control are fundamental for the profitability of the injection molding cell. The TDK units are fully adaptable to any molding condition and are equipped with reliable features and redundant safeties to operate over the entire temperature range. Flow meter options and connectivity to MiND™ or other Industry 4.0 architectures enable complete process monitoring and data recording.

|

|

MICROGEL RSD Series |

Microgel RS Series

The distinctive product brand of Frigel. High performance Single and Dual Zone TCUs with Booster Pumps and Integrated Portable Chillers

Frigel releases the full range of Microgel RS for Injection Molding. These unique single zone (RSM) and dual zone (RSD) machine-side temperature control units are designed for molding throughputs ranging from 10 to 240 kg/hr . The new Microgel RS range includes important advancements in temperature accuracy over the entire control range (-5 to 90°C), functionalities, pumping performance and overall energy efficiency

The RS range features additional configurations specifically designed for Packaging (RSP) and Extrusion (RSB). Options such as flowmeters, VFDs, return/remote temperature sensors enable full process control capability. Its new user interface offers a flawless experience and full connectivity and interoperability via the Frigel MiND™ platform.