|

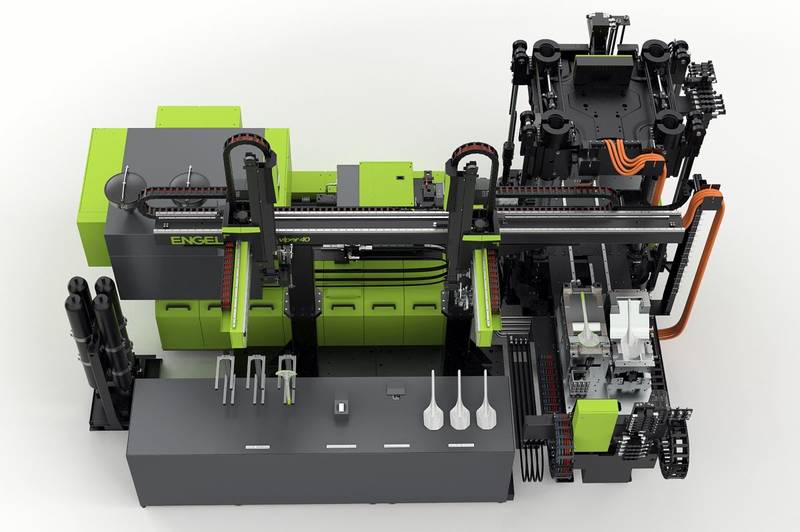

| In partnership with Schöfer, ENGEL has developed a pre-series manufacturing cell for the manufacture of thermoplastic fibre-reinforced components using the in-situ polymerisation technology. |

Thanks to its vast experience in automation and injection molding, ENGEL AUSTRIA provides concepts for composite part production that are very cost-effective. The Austrian manufacturer focuses its development activities on accelerating the implementation of lightweight technology innovations for large-scale batch production. These days, ENGEL is taking part in Composites Europe in Düsseldorf, Germany, to premiere its solutions for pre-series production in the automotive and other sectors.

Ready-to-fit parts single-step produced form plastic pellets are among the most advanced practices in today’s injection molding. Still, when it comes to producing lightweight components directly from non-crimp or dry fabrics, the process has not been comparably efficient yet. Among the current industry solutions, High-Pressure Resin Transfer Molding (HP-RTM) technology developed by Hennecke is the one that approaches single-step manufacture of ready-to-fit components from dry preforms the best. In-situ polymerization of ε-Caprolactam is another opportunity in this field, and the participation of ENGEL in the trade show will cover the combination of this process with injection molding in detail. In addition to offering a greater production performance, this integrated solution supports the growing interest in using matrix thermoplastics.

Injection molding and in-situ polymerization: Better together

In-situ process in an injection molding machine combines molding and polymerization, using pre-shaped dry reinforcing fabrics as support. Since the very first machine prototype was born, ENGEL has been bettering its components; a totally new reactive unit was developed for the possibility of working with various ENGEL machine types. ENGEL pioneered the offer of customized solid monomer melting/processing, for benefits such as greatly reduced heat load and the consequently higher part quality. The company sees here an important potential for carmakers and not only, as any technical injection molding application may take advantage of the solution.

A pre-series production cell for the manufacture of thermoplastic parts with fiber reinforcement was developed by ENGEL together with Schöfer from Schwertberg, Austria. A possible application, shovels are being manufactured on an ENGEL v‑duo 1560/700 machine for demonstration. A sliding table with two mold halves makes the clamping unit highly accessible. Pre-shaped dry fabric is put in the 1st cavity for infiltration with a reactive matrix. The reactive unit melts solid ε-Caprolactam and meters it. This monomer boasts low viscosity when molten, which makes the impregnation of dry fibers especially efficient. The resulting composite, polymerized to PA 6, is very resilient. This reactive processing phase does not require temperatures over the polymer melting point, so the semi-finished composite is easily transferred to the 2nd cavity for further functionalization by injection molding. Injected PA 6, reinforced with short glass fibers, forms shovel ribs and contours. Thus, polymerization and injection molding go on simultaneously. Handling and transfer of fiber preforms and finished items are done by a double ENGEL viper 40 robot.

ENGEL v-duo are energy-saving low footprint injection molding machines developed particularly for fiber composite applications and multicomponent production with fiber preforms. These machines allow for an easier work thanks to a vertical clamping unit accessible from the four sides. Considering a lack of dimensional stability of semi-finished items, it is a significant advantage for a machine operator.

Extreme thin-wall technology enhances processing of thermoplastic fabrics

|

| In the production of notebooks, tablets, smartphones and other hand-held devices, the use of innovative composite materials for housings is key to reducing weight and improving stability. |

ENGEL’s booth at Composites Europe also focuses on thermoplastic fabrics, which are semi-finished parts reinforced with continuous fibers. These fabrics can be processed by injection molding, and ENGEL is displaying and example from mobile device manufacture. Innovations in composite materials are critical for weight reduction and stability improvement of notebook, smartphone, or tablet housings. In partnership with two German companies, LEONHARD KURZ from Fürth and Bond-Laminates of LANXESS Group, based in Brilon, ENGEL successfully developed a high-performance manufacturing cell for the production of outstandingly rigid housings with quality surface finish. The extreme thin-wall technology allows for thicknesses as low as 0.6 millimeters, which paves the way for unseen possibilities.

The production cell is fully automated and designed with the combination of Tepex® thermoplastic fabric and IMD film patented by Bond-Laminates and LEONHARD KURZ in mind. The processing solution integrates three distinct technologies for IMD support in large-scale production of thermoplastic composite parts. First, ENGEL organomelt is responsible for shaping and functionalization of thermoplastic fabrics in injection molding. Then, ENGEL variomelt variothermal mold temperature control for optimizing of surface quality. And finally, the In-Mold Decoration (IMD) itself for attaining the required surface finish directly in the mold. The production cell is built around an ENGEL insert 500V/130 single IMM, an infrared oven for fabric heating, and an ENGEL easix 6-axis robot, all the three developed and supplied by ENGEL.

The new processing technique is unique in the sense that shaping, overmolding and high-quality IMD of the fiber-reinforced preform are done in a single step. In order to guarantee proper bond between the fabric and the IMD film, LEONHARD KURZ and Bond-Laminates developed improved materials, updated the mold and bettered the technology. Thus started a new-level process integration, as opposed to the traditional process where composite parts have to go through additional treatment and painting after injection molding. Integrated processing eliminated multistep production altogether. Both the infrared oven and the multiaxis ENGEL easix robot are completely integrated with the CC300 control unit, allowing for preheating control of semi-finished items from the central display of the injection molding machine. Data on processing temperature and heating time are kept with those on injection molding proper, for a simplified process tracking, evaluation, and documentation.

Infrared ovens by ENGEL boast an excellent thermal homogeneity thanks to individual control of heating zones. They exist in five sizes up to 1,110 × 1,610 mm heating area, for an easier processing of large semi-finished components — for example, those for complete door or front-end modules for cars.

Integrated solutions make lightweight design cost-effective

The most advanced lightweight designs and, consequently, sustainable vehicles could not be imagined with no highly integrated smart processes. If you compare automotive with aerospace industry, production is very large-scale, which makes manufacturers increasingly seek for cost-efficiency. Thus, innovative production methods are crucial for the manufacture of fiber-reinforced plastic items.

|

|

ENGEL recently commissioned a second, larger v-duo machine at its Center for Lightweight Composite Technologies, which is located in St. Valentin. |

To be able to enlarge its application range even further, ENGEL is currently expanding the capacity of the Center. A new 17,000 kN ENGEL v-duo 1700 machine has already been commissioned. This IMM comprises an injection unit aided by an ENGEL easix robot and a high-pressure dosing unit developed for reactive process. It can also be used with ENGEL IR oven. This machine serves both for development purposes and for customer trials.